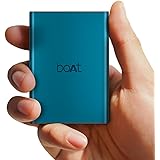

boAt Newly Launched Pocket Energyshroom PB400 Pro 20000mAh | Compact Power Bank w/Type-C Input (2-Way Port), 3X Output Ports,2-Way 22.5W Fast Charging, Pass-Through Charging(Steel Blue)

₹1,699.00 (as of December 25, 2024 20:35 GMT +05:30 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Sustainable packaging is becoming increasingly important as the world grapples with environmental challenges such as plastic pollution, deforestation, and the growing carbon footprint of industries. As a result, companies are actively seeking alternatives to traditional packaging materials that are environmentally friendly and economically viable. Molded pulp, a material derived from recycled paper products and other fibrous plant-based materials, is emerging as a game-changer in the packaging industry. This article explores how molded pulp is revolutionizing sustainable packaging solutions by providing a more eco-friendly and versatile option for manufacturers and consumers alike.

What is Molded Pulp and How Is It Made?

Molded pulp is a biodegradable material made from recycled paper, cardboard, or other fibrous materials that are processed into a pulp, molded into specific shapes, and then dried. This process can be adapted to create packaging that mimics the look and feel of traditional plastic, but without the environmental drawbacks. The pulp is typically mixed with water and formed into molds that define the shape and structure of the final product, such as trays, boxes, or protective packaging inserts. Once the molded pulp takes its form, it is dried in a controlled environment, hardening into a durable, lightweight material ready for use in packaging.

The production of molded pulp is significantly more sustainable than the manufacturing of plastic or foam products, as it relies on renewable resources like recycled paper or plant fibers. Unlike plastic, which takes centuries to decompose and contributes to harmful pollution, molded pulp is completely biodegradable and compostable. Additionally, it can be produced using water-based processes, reducing the need for toxic chemicals often associated with plastic packaging production. The use of renewable resources and the reduction of harmful chemical exposure make molded pulp a highly attractive alternative to conventional packaging materials.

Environmental Benefits of Molded Pulp Packaging

One of the main advantages of molded pulp is its minimal environmental impact compared to traditional packaging options like plastic or styrofoam. Molded pulp is not only biodegradable but also recyclable, meaning that it can be repurposed for future use, helping to conserve natural resources and reduce waste. The material’s compostability allows it to break down naturally when discarded, returning to the earth without leaving behind harmful pollutants. This contrasts sharply with plastic, which can persist in landfills for hundreds of years, contributing to environmental degradation and posing a threat to wildlife.

Furthermore, the production of molded pulp is more energy-efficient than many other forms of packaging. Since it is made from recycled paper or other plant-based fibers, the energy required to produce it is significantly lower than that of manufacturing plastic products from virgin petrochemical materials. Additionally, the low carbon footprint of molded pulp packaging contributes to reducing greenhouse gas emissions, a vital step toward combating climate change. By choosing molded pulp over more energy-intensive and polluting alternatives, companies can make a tangible contribution to environmental sustainability and align their operations with eco-conscious practices.

Molded Pulp in Packaging and Its Versatility

Molded pulp’s versatility in design and application is another key factor driving its popularity as a sustainable packaging solution. This material can be molded into a wide range of shapes and sizes, making it suitable for packaging everything from delicate electronics and fragile food items to industrial products and cosmetics. The design flexibility of molded pulp allows for the creation of customized packaging solutions that meet the specific needs of different industries while still maintaining eco-friendly attributes.

Additionally, molded pulp can provide superior protection for products during shipping and storage. The material is naturally cushioning and shock absorbent, which is essential for safeguarding fragile items from damage. Unlike plastic or foam, which may not break down after use, molded pulp packaging can be reused or recycled without leaving behind harmful residue. This makes it an ideal solution for companies that prioritize both product protection and sustainability. With its ability to be tailored to fit specific products, molded pulp is proving to be a versatile and effective alternative to traditional packaging materials.

The Role of Molded Pulp in Reducing Plastic Waste

Plastic waste is one of the most significant environmental problems facing the world today. Single-use plastic packaging, such as bottles, bags, and food containers, is a major contributor to pollution, especially in the oceans. Molded pulp packaging offers a promising solution to help mitigate plastic pollution. By replacing single-use plastic with biodegradable, compostable, and recyclable molded pulp, companies can reduce their reliance on plastics, thereby lessening the amount of plastic waste that ends up in landfills or the ocean.

The widespread adoption of molded pulp in various industries can contribute to a significant reduction in the production and disposal of plastic packaging materials. Major industries, including food and beverage, electronics, and e-commerce, are increasingly turning to molded pulp as a viable alternative to plastic packaging. As consumer demand for sustainable products continues to rise, companies that embrace molded pulp packaging will not only help reduce plastic waste but also align themselves with growing environmental and ethical standards. The shift from plastic to molded pulp is an essential step toward a more sustainable future.

The Future of Molded Pulp in Sustainable Packaging

As awareness of environmental issues grows, the future of molded pulp in sustainable packaging looks promising. With continuous advancements in materials science and manufacturing technologies, the capabilities of molded pulp are expected to expand, allowing for even more specialized applications in the future. The material’s ability to be used in a variety of industries, from consumer goods to electronics and food packaging, positions it as a key player in the transition toward a circular economy.

Moreover, as governments and regulatory bodies implement stricter environmental policies and regulations, the demand for eco-friendly packaging materials like molded pulp will likely increase. Companies that adopt sustainable packaging solutions will not only benefit from a competitive advantage in a market that values environmental responsibility but will also contribute to the long-term health of the planet. The rise of molded pulp as a sustainable packaging material is a clear indication of the growing importance of eco-conscious choices, and its continued development will be essential to driving the future of sustainable packaging.

Conclusion

Molded pulp is revolutionizing sustainable packaging by providing an environmentally friendly alternative to traditional packaging materials like plastic and foam. With its ability to be molded into various shapes, its biodegradability, and its recyclability, molded pulp offers a versatile and eco-conscious solution to meet the demands of both manufacturers and consumers. As the world continues to face pressing environmental challenges, molded pulp stands as a shining example of how innovative materials can drive change toward a more sustainable and waste-free future. By adopting molded pulp, businesses can make a positive impact on the planet while offering their customers packaging that aligns with their values and needs.

0 Comments