Samsung Galaxy M31 (Blue, 6GB RAM, 64GB Storage)

(as of March 21, 2025 21:07 GMT +05:30 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)When selecting stainless steel springs for your projects, it’s crucial to choose the right material and quality to ensure durability, flexibility, and overall performance. Here's a guide on how to identify strong stainless steel springs, including custom compression springs, custom torsion springs, and other tailored solutions that will meet the specific requirements of your project.

1. Understanding Stainless Steel for Custom Springs

Among all materials used for custom springs stainless steel stands out because it offers superior strength together with strong resistance to corrosion. The selection of suitable stainless steel alloys for your needs requires full comprehension when choosing springs.

Three prevalent stainless steel grades used for manufacturing custom springs consist of:

● Austenitic Stainless Steel (300 Series): The 300 Series of Austenitic Stainless Steel includes stainless steel grades 302 and its iterations 304 and 316. These specific alloys demonstrate excellent resistance to corrosion so they become an ideal solution for springs operating in wet or chemical environments.

● Martensitic Stainless Steel (400 Series): Steels within the 400 Series as Martensitic Stainless Steel bring high tensile strength through grades 420 along with 430, which find usage in strong springs needing maintenance of design despite substantial mechanical stress.

●Precipitation-Hardening Stainless Steel: The storage of stainless steel alloys using precipitation techniques leads to exceptional strength that makes them suitable for custom spring applications needing particular mechanical properties.

2. Effective Spring Constant for Strong Springs

The identification of strong springs hinges on the comprehension of the effective spring constant, which is alternatively termed as spring stiffness or rigidity. The effective spring constant establishes the required amount of force needed to deform the spring according to a specific distance. The strength of custom springs grows with higher spring constants since these springs exhibit better resistance to external loads.

3. Strength and Durability

The surface durability of stainless steel springs depends on both material tensile strength and the ability to handle repeated stress cycles. Choose stainless steel springs, particularly custom compression springs or custom torsion springs, which demonstrate high fatigue limits when cycles of tension or compression will be present in your project.

4. Corrosion Resistance

The resistance of stainless steel to corrosion serves as the primary factor that makes this material ideal for creating springs. The protection level against chloride-induced corrosion increases when selecting 316 stainless steel over other stainless steel grades for applications involving harsh environments such as marine or industrial settings.

5. Spring Design Considerations for Custom Springs

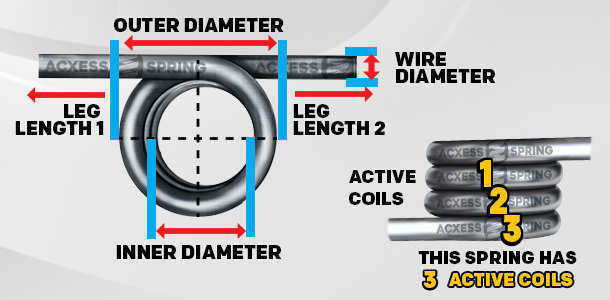

Manufacturers design customised springs using all types of springs from compression to torsion and more kinds. The performance strength of a spring can be influenced by three main design variables which consist of wire diameter together with both coil diameter and number of coils.

● Compression springs: Stainless steel compression springs exist for suppressing compressive forces because such applications need these springs to support strength retention that protects shape and functional capabilities when under load.

● Torsion springs: Torsion springs work as twisting-force resistors, which find applications in setups needing rotational motion movements. The mechanical systems that demand accurate torque resistance rely on custom torsion springs that use stainless steel for fabricating the components.

6. Choosing the Right Custom Spring Manufacturer

A proper selection of reputable custom spring manufacturers enables users to obtain dependable stainless steel springs with high quality. As a first step, choose manufacturers who both specialise in producing custom springs and have stainless steel materials available with expert production methods, including cold winding and heat treatment.

Conclusion

Identifying strong stainless steel springs for your projects involves understanding the right material properties, such as tensile strength, corrosion resistance, and spring constant. Always choose a reputable manufacturer to ensure your project benefits from high-quality custom springs tailored to your exact specifications.

0 Comments